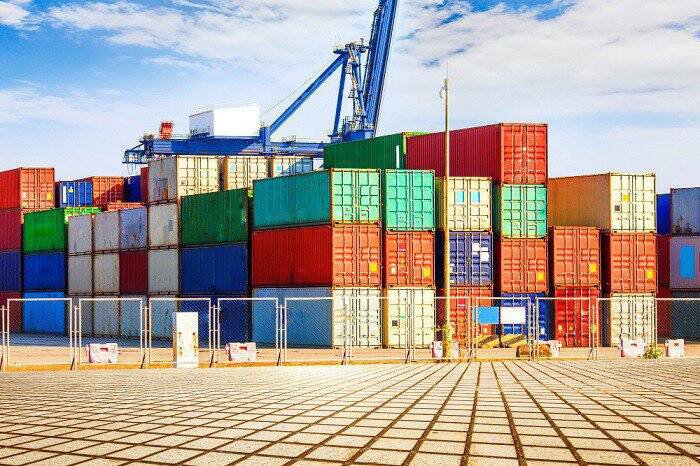

Shipping containers have evolved into the foundation of the transportation sector in the globalized world of trade and commerce. Large steel shipping containers like these link producers and customers worldwide by transporting goods over great distances. However, it is more than just a matter of luck that these containers travel without incident from port to port. Container stowage planning involves the meticulous planning and strategic placement of these containers behind the scenes.

This article explores the importance of container stowage planning and explains why it is essential to ensuring the effectiveness and safety of maritime transportation.

The Basics of Container Stowage Planning

Planning the placement of shipping containers on a ship to make the best use of available space, maintain stability, and protect the cargo and the ship from harm is known as container stowage planning. It entails pinpointing each container's location while considering variables like cargo type, weight distribution, and ship stability. Tools like a CBM calculator can complement this process by ensuring accurate volume measurements, which are crucial for optimizing container placement. Usually, specialized software is used to carry out this planning to create an effective stowage plan by considering several parameters and restrictions.

Factors Influencing Container Stowage Planning

Several crucial factors influence the container stowage planning process:

Weight Distribution

Weight distribution across the vessel is among the most important components of stowage planning. Unbalanced weight distribution can cause stability problems, which raises the risk of mishaps like capsizing. The ship's stability can be preserved by carefully arranging heavier containers lower in the hold and lighter ones higher up.

Cargo Type

The requirements for stowage vary depending on the type of cargo. Hazardous materials must be handled carefully and isolated, while oversized cargo necessitates special arrangements. Perishable goods may need to be stored close to refrigeration units. To ensure safe transportation, effective planning considers the variety of cargo.

Design of the Vessel

Stowage planning is also impacted by the particular design of the vessel. Plans must be specifically designed to consider the special features of vessels with multiple decks, different container capacities, and various loading techniques.

Port Calls and Discharge Sequence

Stowage planning must consider both the order in which containers will be discharged at various ports and their initial loading. Containers meant for early discharge should be stored closer to the deck, while those intended for ports later in the voyage can be stored inside the ship.

Stability and Trim

Maintaining the ship's stability and trim, or the harmony between the bow and stern, is crucial for safe navigation. A balanced vessel handles choppy waters more skillfully, lowering the possibility of accidents.

The Significance Of Container Stowage Planning

The importance of efficient container stowage planning cannot be overstated. Here's why it plays a pivotal role in the maritime industry:

Maximizing Space Utilization

There is a limited amount of space on a cargo ship. Every square inch of the available space is utilized effectively with the help of a well-designed stowage plan. This increases the number of containers transported in a single voyage, minimizing the need for additional trips and maximizing operational costs.

Time Efficiency

A well-organized stowage plan speeds up port loading and unloading. Accessing containers headed for a particular port is simple, reducing delays and streamlining operations.

Cargo security

Improperly stowed cargo may be susceptible to damage. Containers not properly secured could move during transport, potentially causing delays and losses. A carefully thought-out stowage plan reduces the possibility of cargo loss and damage.

Maintaince

Maintaining the ship's stability is essential for the crew, the cargo, and overall safety. The likelihood of accidents rising as a result of an inadequate stowage plan.

Regulation Compliance

The maritime sector is governed by several laws relating to the movement of goods, environmental protection, and safety. Stowage planning must abide by these rules to avoid legal trouble and penalties.

Cost-Effectiveness

Good stowage planning helps cut costs by using resources more efficiently, using less fuel, and reducing operational delays.

Advanced Technology In Container Stowage Planning

The planning process for container stowage has revolutionized in recent years thanks to technological advancements. Modern software systems use simulation models, real-time data, and algorithms to create optimized stowage plans. These systems can quickly consider various factors and produce plans that balance all pertinent elements, from stability to weight distribution.

Conclusion

Planning container stowage is crucial to the maritime sector, ensuring worldwide effective and secure cargo transportation. The complex procedure considers various variables, including cargo type, weight distribution, vessel design, and stability. Stowage planning is essential in determining how the modern logistics landscape will look by maximizing space utilization, improving time efficiency, guaranteeing cargo safety, and adhering to regulations. Planning for container stowage holds even more promise as technology develops, promising more streamlined, efficient, and secure maritime transportation.

Get instant quote

and compare offers in real time

Get instant quote

and compare offers in real time